Combining diversity of product offerings with prompt customer responsiveness to meet requirements of varied sectors...

Company Brief

A 4000 cr group, D P JINDAL GROUP is renowned as Indiaâs largest Steel Pipe conglomerate with wide business visibility across major industrial sectors such as Oil Well Drilling, Power Generation, and Finance & Leasing. Empowered with a strong work force of over 2500 personnel, the group has emerged as a key manufacturer & exporter of Seamless and ERW pipes, with enviable export coverage across USA, Africa, Middle East, Bangladesh & Myanmar.

As of now, the following companies fall under the corporate umbrella of the prestigious Jindal Group:

- Maharashtra Seamless Limited: This Company specializes in manufacturing Seamless Pipes & Tubes, ERW Pipes, and also deals in Wind Power Generation.

- Jindal Pipes Limited: It is engaged as a manufacturer of ERW Black and G.I. Pipes.

- Jindal Drilling & Industries Limited: It deals in Offshore Drilling for Oil & Gas.

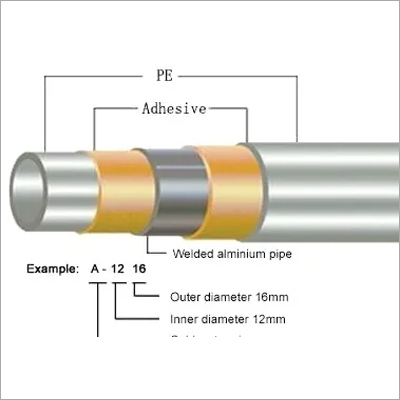

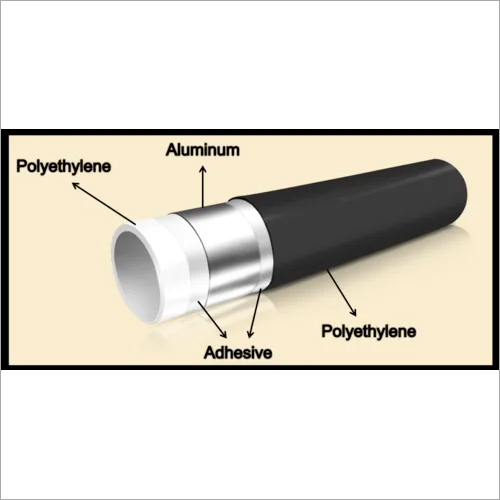

- Jindal Composite Tubes Pvt Ltd: Jindal Composite Tubes Pvt Ltd, is an integral business arm of Jindal Group. Steered by the parent company, it forayed into business as an importer of Multilayer Composite Pipes and its related fittings way back in 2003. Back then, it was among the very first to Launch Composite Pipes or Pe-al-Pe Pipes in India with wide range of pipes for Hot, Cold & Gas Supply, and even today the company is a reckoned as a leading global player with unmatched excellence marks in its domain.

- Jindal Pex Tubes Pvt Ltd

Currently,

Jindal Pex Tubes is counted amongst the finest producers of Composite

Pipes & related Plastic fittings in India. These pipes are

manufactured using best-of-breed design concepts in strict consonance

with BIS Standard IS 15450 & ASTM F1282. Jindal now has in stock a

wide range of Plastic Pipes like Agriculture Selffit & Ringfit

Pipes, Water Extraction System (Casing Pipe), Threaded/Plain Pipes for

Domestic Plumbing, Sewerage Pipes, Column Pipes, HDPE Pipes, CPVC Pipes

& Fittings, and much more, which are fabricated in varying sizes and

configurations ranging from 20mm to 315mm, to suit client's specific

end-use application and requirements.

Qualitative Product Line

Keeping

in mind Jindal's long-term goal of capturing a sizable market share as a

global, multi-product, multi-brand company, we, Jindal Pex Tubes

manufacture and market a quality-proven line of Plastic Pipes, such as:

- Agriculture Selffit & Ringfit Pipes

- Water Extraction System (Casing Pipe)

- Threaded, Plain Pipes for Domestic Plumbing

- Sewerage Pipes

- Column Pipes

- HDPE Pipes

- CPVC Pipes & Fittings, and more...

Diversified Application Areas

Jindal

Pipes are suitably employed in a range of different application areas.

Some of the sectors wherein Jindal manufactured Pipes and Fittings are

extensively used are:

- Agriculture

- Housing

- Sanitary

- Plumbing

- Bore Well

- Water Extraction

- Telecom etc.

The Quality Seal of Jindal

Sustaining

high benchmarks of quality is a part of Jindal's daily policy. In line

with this, the company appoints and nurtures a group of professionals

who in turn are guided by a board of Directors consisting of eminent

personalities. The entire group is led by the innovative and dynamic

Sahil Jindal, Director of the Group Company with a distinguished record

of contributions to the industrial development in India. Under his

inspiring headship, Jindal strives to attain the following objectives:

- Involving employees in the implementation of a quality policy

- Assigning each employee specific task and individual responsibility as per this policy

- Encouraging and supporting specific skill sets of employees through specific training programs and workshops

- Maintaining a conducive work environment to guarantee the health and safety of employees

- Utilizing natural resources and energy efficiently, also working towards minimizing impact of its production activities on the environment

- Conducting intensive tests on raw materials, end products, etc., on the basis of well-regulated quality control parameters

- Organizing business activities in a fair and responsible way whilst fully conforming to various legal provisions

- Maintaining a well-knit distribution network all over India and worldwide, thus giving customers quick product accessibility

- Promptly responding to customer queries and making 'customer satisfaction' the foremost priority, always.

|

|

|

|

JINDAL PEX TUBES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry